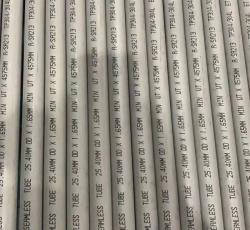

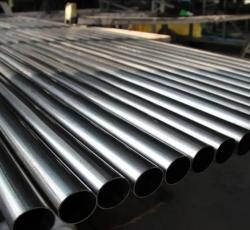

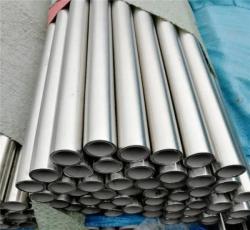

Overview of ASTM A778 Steel Pipe Scope: Purpose: ASTM A778 covers welded, unannealed, austenitic stainless steel tubular products intended for general corrosive service and low- or high-temperature applications. Applications: These pipes are commonly used in applications where corrosion resistance and mechanical properties of stainless steel are required, such as in structural, decorative, industrial, and architectural applications. Materials: Stainless Steel Grades: ASTM A778 specifies various grades of austenitic stainless steel, including 304, 304L, 316, 316L, 317, 321, and others. These grades are selected based on their corrosion resistance, mechanical properties, and suitability for specific applications. Manufacturing Process: Welding: Pipes are manufactured by welding stainless steel strip or plate, which may be formed into a tubular shape and then welded longitudinally. Annealing: ASTM A778 pipes are typically supplied in the welded condition without subsequent heat treatment (unannealed). Specifications: Dimensions: Pipes are available in various sizes with specified outer diameter (OD) and wall thickness (WT). Types: ASTM A778 specifies two types of pipes: Type 1 (round, square, rectangular) and Type 2 (round only). Surface Finish: Pipes may be furnished with a variety of finishes, including annealed pickled, bright annealed, or polished finishes as specified. Mechanical Properties: Tensile Strength: Pipes must meet specified tensile requirements depending on the grade of stainless steel used. Elongation: Requirements for elongation are also specified to ensure adequate ductility of the pipes. Testing and Inspection: Mechanical Tests: Pipes undergo mechanical tests such as tensile strength test, hardness test, and flattening test. Non-Destructive Testing: ASTM A778 requires non-destructive testing methods like eddy current or ultrasonic testing to ensure the integrity of welds and overall pipe quality. Visual Inspection: Pipes are visually inspected for surface defects, dimensions, and adherence to specifications. Standards and Compliance: ASTM A778: Standard specification for welded, unannealed, austenitic stainless steel tubular products. Compliance: Pipes manufactured under ASTM A778 conform to rigorous standards ensuring they meet the specified requirements for corrosion resistance, mechanical properties, and dimensional accuracy. Advantages: Corrosion Resistance: Stainless steel grades specified in ASTM A778 exhibit excellent resistance to corrosion in various environments, including acidic and chloride-rich conditions. Versatility: Suitable for a wide range of applications due to their corrosion resistance, strength, and aesthetic appeal. Longevity: Stainless steel pipes are known for their durability and long service life, even in demanding industrial applications. Conclusion: ASTM A778 steel pipes are integral components in industries requiring reliable, corrosion-resistant tubing for structural, decorative, and industrial applications. Their adherence to ASTM standards ensures they deliver consistent performance and durability in diverse environmental and operational conditions.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

(4)_1729176674.png)