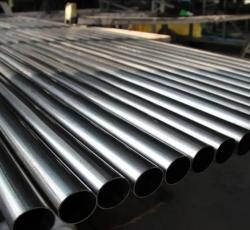

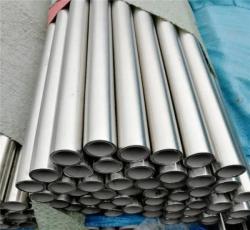

Butt-Welded Pipe Description: Butt-welded pipe is created by feeding a heated steel plate through shapers that roll it into a hollow, circular form. The two ends of the plate are then forcibly squeezed together to produce a fused joint or seam. This process ensures a strong, uniform connection along the length of the pipe. Advantages: Uniform Wall Thickness: Butt-welded pipes have a consistent wall thickness, making them suitable for applications requiring precision. Inspection Capability: The rolled plate can be inspected for defects before forming and welding, ensuring higher quality control. Applications: Butt-welded pipes are particularly useful for applications requiring thin walls and long lengths. They are ideal for various industrial uses where high strength and uniformity are essential. Spiral-Welded Pipe Description: Spiral-welded pipe is formed by twisting strips of metal into a spiral shape, similar to a barber’s pole. The edges of the spiral are welded together to form a seam. Due to their construction, these pipes have thinner walls and are typically used in low-pressure systems. Advantages: Economical: Spiral-welded pipes are cost-effective for low-pressure applications. Long Lengths: They can be produced in long continuous lengths, reducing the need for additional joints. Limitations: Wall Thickness: The thin walls limit their use to low-pressure applications. Strength Factor: Spiral-welded pipes have a lower strength factor, assigned 60% by the American National Standards Institute (ANSI). Manufacturing Standards The American National Standards Institute (ANSI) has established strict guidelines for pipe manufacturing. The Pressure Piping Code B31 governs the production standards: Butt-Welded Pipe: Assigned a strength factor of 85%. Spiral-Welded Pipe: Assigned a strength factor of 60%. Seamless Pipe: Assigned a strength efficiency of 100%. Seamless Pipe Description: Seamless pipes are known for their wider wall thickness and are typically produced in single and double random lengths. Single random lengths range from 16 to 20 feet, while double random lengths for pipes 2 inches and below range from 35 to 40 feet. Advantages: High Strength: With a strength efficiency of 100%, seamless pipes are suitable for high-pressure applications. Wide Applications: Ideal for uses requiring greater wall thickness and durability. Summary Each pipe manufacturing method offers unique advantages and is suited to different applications. Butt-welded pipes are excellent for high-precision and thin-wall applications. Spiral-welded pipes provide an economical solution for low-pressure systems. Seamless pipes offer the highest strength and are versatile for a wide range of uses.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

(4)_1729176674.png)