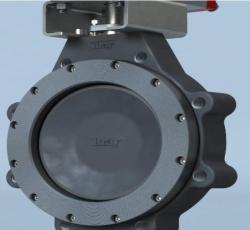

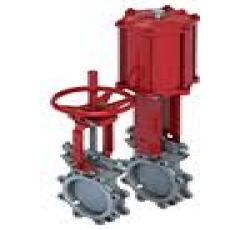

The High Performance Triple Offset Butterfly Valve is an essential component in pipeline systems across diverse industries including petroleum, chemical, metallurgy, and hydropower. Engineered with advanced sealing technology, this valve excels in applications requiring high resistance, pressure, corrosion resistance, and wear resistance.

Key Features:

Advanced Sealing Structure: Utilizes rubber, polytetrafluoroethylene (PTFE), and other high-performance materials for superior sealing under extreme conditions.

Robust Construction: The valve body and seat are integrated components, with the seat's sealing surface reinforced using a temperature and corrosion-resistant alloy material like stellite, ensuring durability and reliability.

Wide Application Range: Suitable for environments with temperatures up to 800°C and pressure ratings from Class150 to 900LB (PN6 to PN100), accommodating demanding industrial applications.

Materials: Constructed from high temperature steel, stainless steel, duplex steel, and other alloys to withstand harsh operating conditions.

Packing Material: Equipped with flexible graphite packing for reliable sealing and minimal friction.

Specifications:

Size: 2”~72”

Main Materials: High Temperature Steel, Stainless Steel, Duplex Steel etc.

Stem Material: XM-19, Duplex Steel, Inconel X-750

Packing Material: Flexible Graphite

Seat Material: Stellite

Temperature Range: ≤800℃

Design and Manufacture Standards: API 609

Face-to-Face Standards: API609, ASME B16.10, ISO 5752

Ends Connection: Flange, Wafer, Lug

Inspection & Testing: API 598, EN12266

Operation: Available with Lever, Worm Gear, Electric, or Pneumatic actuators for diverse operational needs.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.png)

(4)_1729176674.png)