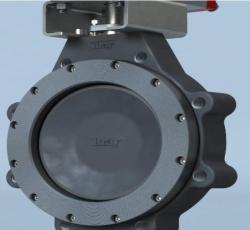

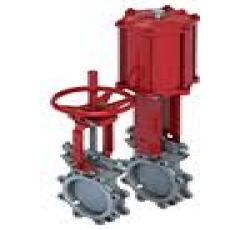

The Fire Safe Double Offset Butterfly Valve is designed with a unique product structure, ensuring superlative sealing performance, wide applicability, low operation torque, extended service life, and safety in special working conditions. This high-performance valve series utilizes a range of structural materials, including NACE compliant and abrasion-resistant components, making it ideal for applications involving cryogenic, steam, chlorine, oxygen, high vacuum, corrosive medium, and low-temperature environments.

Key Features:

Double Eccentric Design: Enhanced from the single eccentric butterfly valve, the double eccentric design positions the valve stem axis away from the center of both the butterfly plate and the body. This configuration allows the butterfly plate to swiftly detach from the valve seat upon opening, minimizing unnecessary friction, reducing wear, and improving seat life. It enables the use of metal seats, enhancing suitability for high-temperature applications.

Superior Sealing: Utilizes materials such as RPTFE and PPL for exceptional sealing performance across a wide temperature range from -40℃ to 260℃.

Fire Safe Design: Ensures reliability and safety in critical and fire-prone environments, meeting stringent industry standards.

Wide Application Range: Suitable for various media including water, steam, gas, oil, acetic acid, and nitrose, providing versatility in industrial applications.

Specifications:

Models: LTD72F/H, LTD372F/H

Size Range: 2”~64”, DN50-DN1600

Pressure Rating: ANSI 150LB, PN10~PN16

Body Materials: ASTM A216 WCB, ASTM A351 CF8/ CF8M/ CF3/ CF3M etc.

Seat Materials: RPTFE, PPL

Temperature Range: -40~260℃

Design and Manufacture Standards: EN593

Face-to-Face Dimension: EN558-1

Ends Connection: Wafer

Inspection & Testing: EN12266

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.png)

(4)_1729176674.png)